Our small team of crafters have refined skills and have seen countless watches pass through their steady, careful hands. The room is quiet as the lone crafter on this early morning begins the day’s orders. Seated before his table of tools, he perfectly situates all the needed pieces at arms length. This is his domain. The bright lights focus on the tools he’s freshly aligned and set about the clean, white table; he can never be too careful even in setting up his space. The fog has rolled in, blocking out the sun, but his lamps are a faithful substitution. A salty, San Francisco breeze chills the room momentarily, but he does not notice. His focus lies elsewhere. He is busy inspecting the unique color and swirls of the wood.

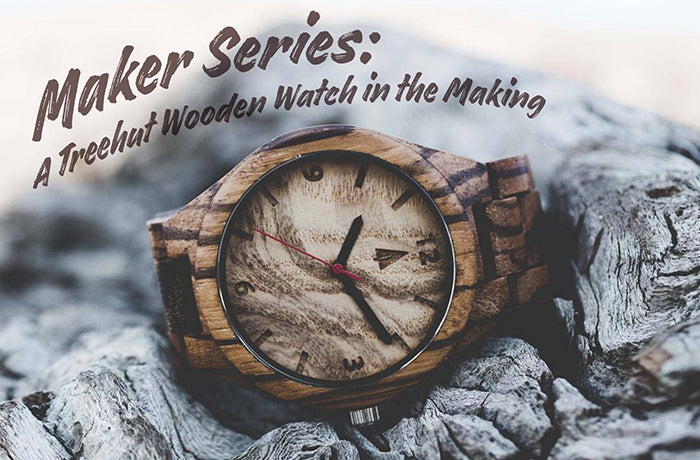

This beautiful piece of wood is Olive Ash Burl. Each piece of natural wood is unique like a snowflake or fingerprint. Looking closely, the lines whirl around creating random distinct patterns within the same piece. Our crafter is fastidiously looking for any knots that could diminish the quality of the face to come.

Related article: What is Burl Wood? It's Weirder Than You Think!

After inspecting the wood, our crafter carefully places the wood in our engraving machine, which then cuts out the face with engraved time marks.

With the face and notches in place, he lays out the three time hands. His pinky finger dwarfs the tiny, delicate hands, so once again he reaches for his needle nose pliers. His eyes focus on the center of the face, where he has punched out a tiny hole to affix the hands. One by one he places the hour, minute, and second hand into place. With a gentle push, that bounces back, the hand setter tool has locked the hands into place. They spring to life powered by Japanese quartz movement.

The red second hand has already been hand painted. In some cases the hand is painted at this point, as it spins. The required skill to paint a ticking hand is impressive. His touch is so light and hand so quick that not a single drop falls to the face or to the other time hands.

Next, he delicately inserts the crown. Twisting the crown, he aligns the hands to 12. All three are perfectly aligned, so he knows he has set them just right. If he had misplaced the hands in the center hole, the three hands wouldn't overlap perfectly.

The face is now ready to be inserted in the case. Having set the face within the case, he sets the back plate precisely over the opening. Using an X motion he drills in the small watch screws. The watch is now ready to be engraved with our customer's personalized message.